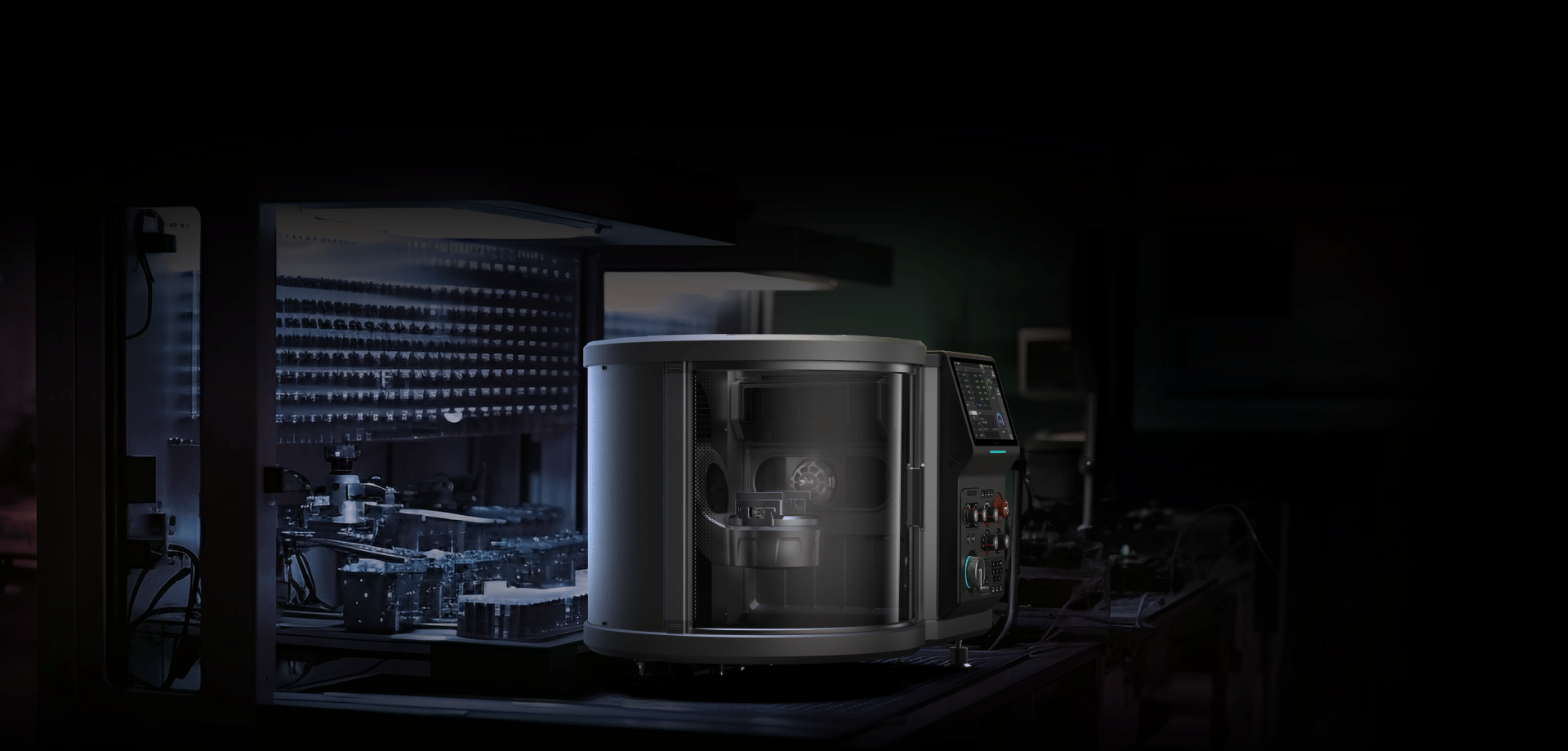

Desktop 5-axis CNC Machine

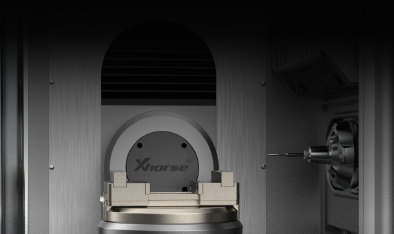

Xmachine

A New Age of Creation

A Perfect Desktop CNC Into Your Work Space

Introducing Xmachine 5-axis CNC machine, a game-changing desktop CNC designed for makers, DlYers, hobbyists, creators, and machin- ists. Its compact body with a sleek modern design makes it ideal for flexible layout arrangements in your space.

If you're looking for a CNC system for homes, schools, shops or small businesses, Xmachine is well up to the task and comes with extraordinarily powerful performance to boot.

The Ultimate in Productivity 5-axis Simultaneous Machining

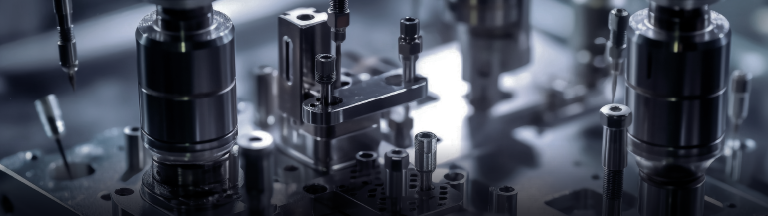

Xmachine introduces 5-axis simultaneous machining capabilities, enabling the production of highly intricate and precise components with unparalleled efficiency and accuracy.

With the ability to maneuverthe cutting tool in multiple directions simultaneously, Xmachine eliminates the limitations imposed by traditional 3-axis machining, opening up new possibilities for designing and manufacturing across industries.

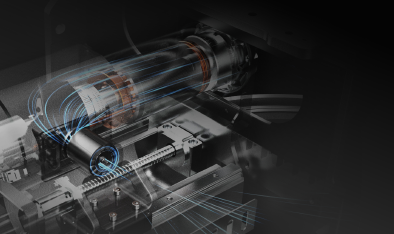

High-Speed Machining Begets High Efficiency

Driven by a permanent magnet synchronous motor, the machine spindle features a built-in inductive encoder and cooling duct, achieving a speed of 18000rpm, ensuring high-speed machining and enhanced productivity rates.

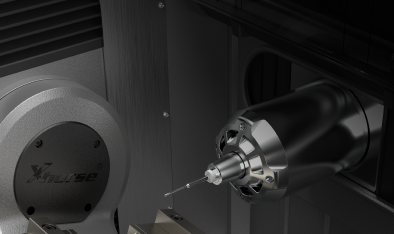

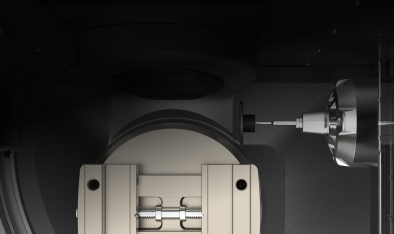

Innovative Concealed Automatic Tool Changer

Xmachine pioneered the concealed automatic tool changer system in desktop milling machines, which automatically unfolds during tool changes and folds during operation, accommodating up to 6 tools.

This innovative system allows for rapid switching between various processes, significantly reducing processing time and increasing efficiency.

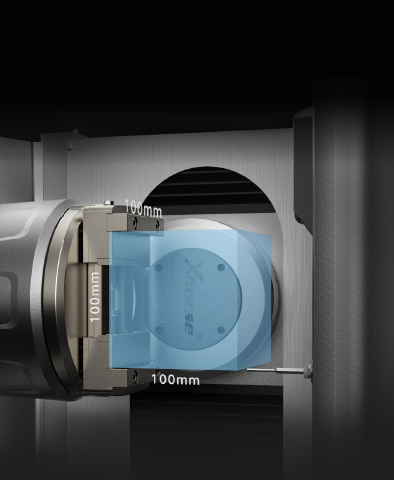

Premium Materials Precision Ensured

The X, Y, and Z linear axes are driven by self-designed servo motors, high-precision linear guides and ball screws.

The A-axis includes a harmonic reducer and a servo motor for enhanced precision.

The C-axis utilizes a self-designed direct drive motor, complemented by self-developed encoders to detect the rotation angle of the worktable, ensuring exceptional precision and swift operation.

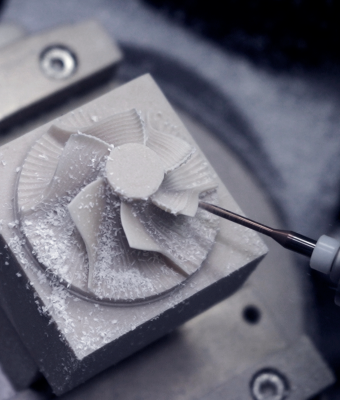

Versatile Machining Capabilities

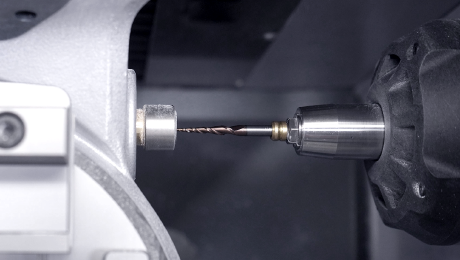

Our state-of-the-art designs pack tremendous performance and capabilities into this compact machining center.

With exceptional stability and rigidity, the machine comes with great capabilities in engraving, milling, drilling, tapping, etc. to flexibly meet the needs of different work.

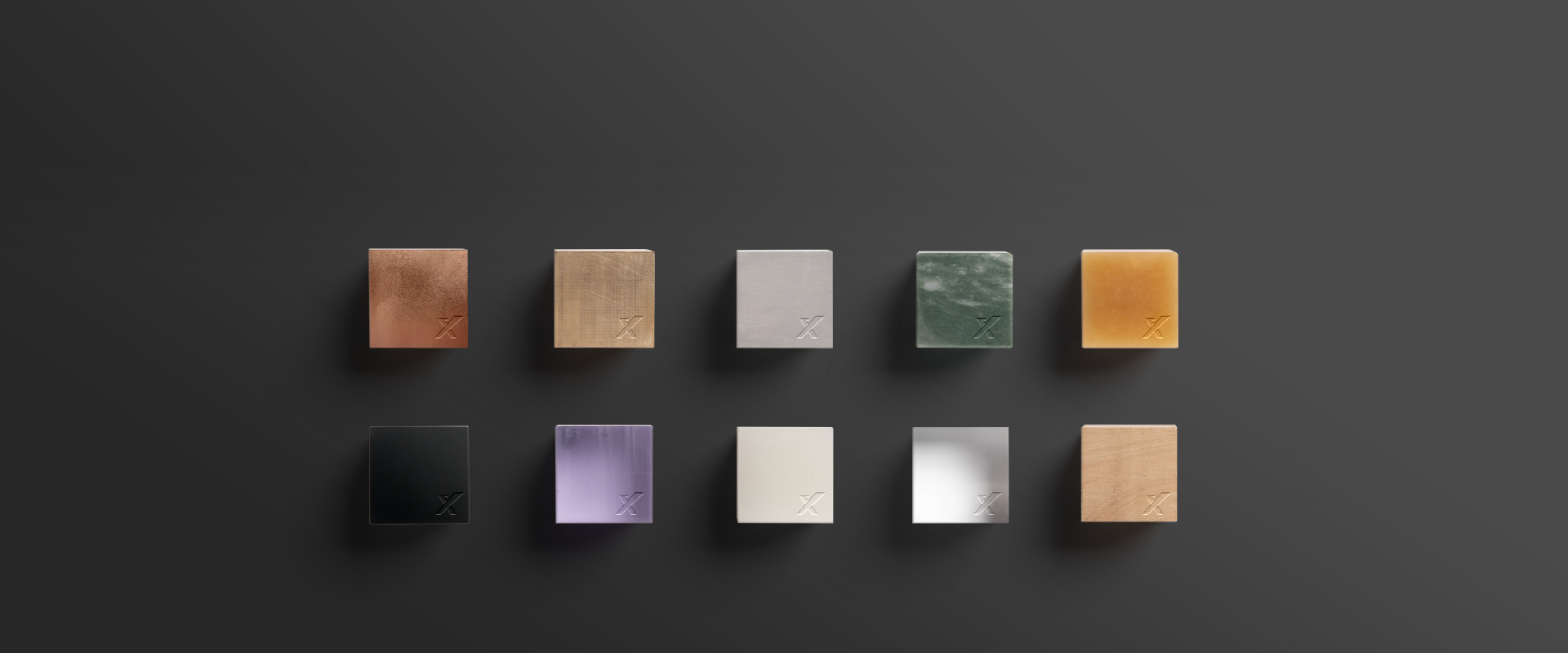

Ideal for Cutting Multiple Materials

The machine excels in handling a wide range of materials, including metals, plastics, and others, showcasing exceptional versatili- ty. The array of materials available offers limitless possibilities for the products achievable on Xmachine.

A Harmony of Design and Experience

The 10" touchscreen provides operators with an intuitive experi- ence to interact with CNC machines, enabling precise control, moni- toring, and optimization of machining processes for efficient and high-quality production.

Intuitive Control Panel

Designed with simplicity in mind, the control panel of this machine, featuring a concise layout for ease of operation, allows users to input commands and control various aspects of the machining process.

Main menuSwitch machining modeEmergency stopSpindle speed overrideFeedrate overrideAxis controlStart or pauseResetI/O controlHandwheel

Main menuSwitch machining modeEmergency stopSpindle speed overrideFeedrate overrideAxis controlStart or pauseResetI/O controlHandwheelDetail Driven, Thoughtfully Designed

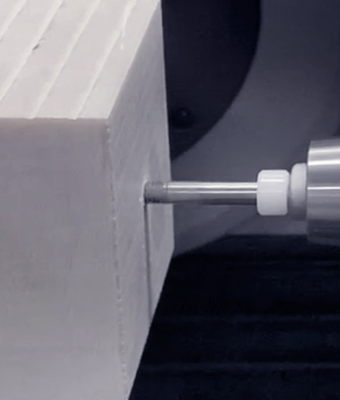

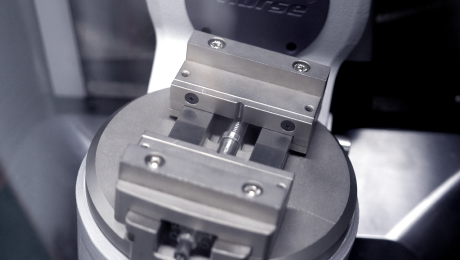

Outfitted with a high-precision self-centering vise on the worktable, facilitating easy and rapid assembly.

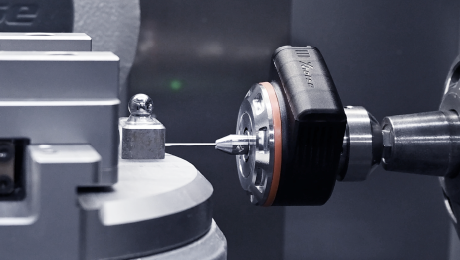

Equipped with a next-gen wireless probe, the machine facilitates fully automatic axis alignment and precise workpiece center measurement.

An automatic tool setting instrument ensures optimal tool alignment and positioning, significantly reducing setup time and extending tool life.

Next-level Controller

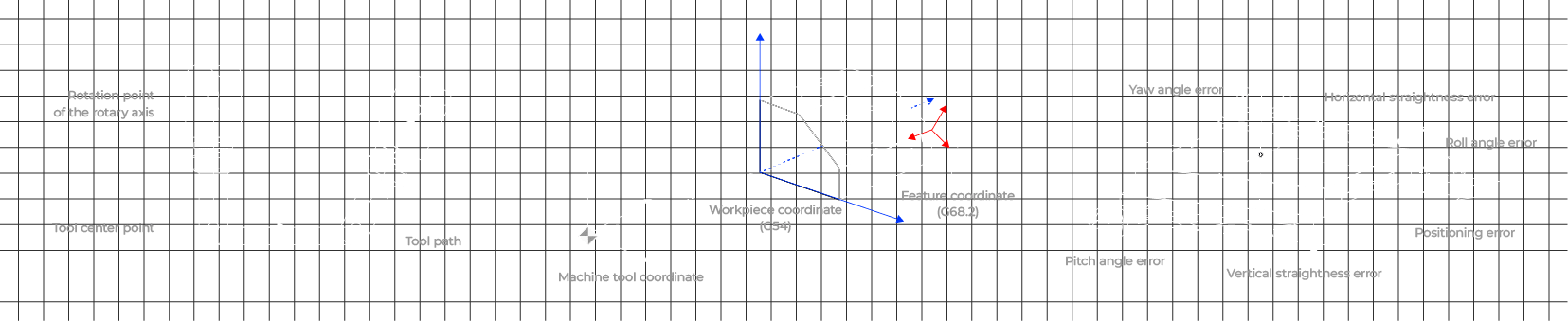

Our self-designed CNC Controller is packed with extraordinarily powerful features including RTCP, 3+2 positioning, error compensation, forward-looking control, flexible interpolation, etc.

Application

Mechanical Components

Competition Designs

Custom Tooling

Artistic Projects

Jewelry and Crafts